Product Description

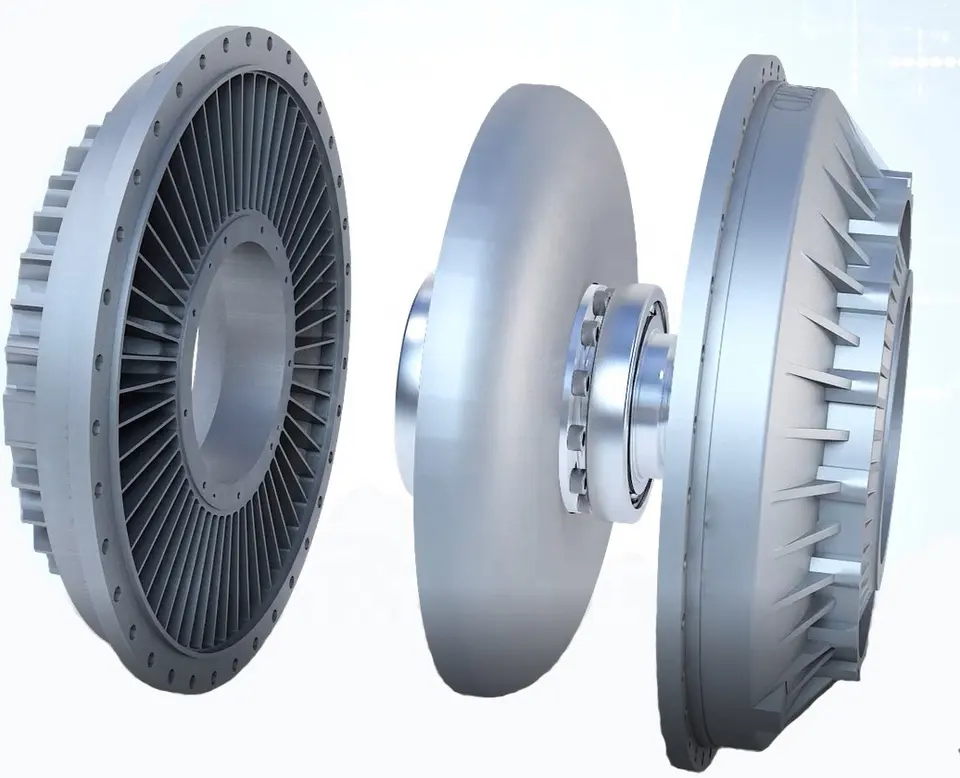

hydrodynamic Jaw Rigid beam Engine Shaft Motor stainless Steel Torque amplifier Torque converter Water brake clutch variable speed fluid Coupling

Application of fluid Coupling

A fluid coupling, also known as a hydraulic coupling, is a hydrodynamic or ‘hydrokinetic’ device used to transmit rotating mechanical power. It has been used in automobile transmissions as an alternative to a mechanical clutch. It also has widespread application in marine and industrial machine drives, where variable speed operation and controlled start-up without shock loading of the power transmission system is essential.

Applications of fluid couplings

Fluid couplings are used in a wide variety of applications, including:

- Automotive: Fluid couplings are used in automobiles to transmit power from the engine to the wheels. They also used in electric vehicles to control the speed of the electric motor.

- Machine tools: Fluid couplings are used in machine tools to transmit power from the motor to the cutting tool. This allows the cutting tool to operate at a high speed and torque, which is necessary for cutting through tough materials.

- Wind turbines: Fluid couplings are used in wind turbines to transmit power from the blades to the generator. This allows the generator to generate electricity at a controlled speed and torque, which is necessary for providing power to homes and businesses.

- Robotics: Fluid couplings are used in robotics to transmit power from the motor to the robot’s joints. This allows the robot to move its joints at a controlled speed and torque, which is necessary for performing tasks such as picking and placing objects.

- Conveyors: Fluid couplings are used in conveyors to transmit power from the motor to the conveyor belt. This allows the conveyor belt to move at a controlled speed and torque.

- Mining: Fluid couplings are used in mining equipment, such as crushers, conveyors, and pumps. The coupling allows the equipment to move materials at a controlled speed and torque, which is necessary for mining operations.

- Construction: Fluid couplings are used in construction equipment, such as excavators, cranes, and loaders. The coupling allows the machinery to move at a controlled speed and torque, which is necessary for construction operations.

- Aerospace: Fluid couplings are used in aerospace applications, such as jet engines and helicopters. The coupling allows the engines to operate at a controlled speed and torque, which is necessary for flight.

Advantages of fluid couplings

Fluid couplings offer a number of advantages over other types of couplings, including:

- Smooth start-up: Fluid couplings allow for a smooth start-up of the driven machine, without the shock loads that can be caused by other types of couplings.

- Variable speed operation: Fluid couplings can be used to vary the speed of the driven machine, without the need for a separate speed control device.

- Shock absorption: Fluid couplings can absorb shock loads, which can protect the driven machine from damage.

- Efficiency: Fluid couplings are very efficient, with losses typically less than 5%.

- Durability: Fluid couplings are very durable and can withstand a wide range of operating conditions.

Disadvantages of fluid couplings

Fluid couplings also have a few disadvantages, including:

- Cost: Fluid couplings can be more expensive than other types of couplings.

- Size and weight: Fluid couplings can be larger and heavier than other types of couplings.

- Maintenance: Fluid couplings require regular maintenance, such as checking the fluid level and replacing the filter.

Overall, fluid couplings are a versatile and valuable tool for a variety of applications. They offer a number of advantages over other types of couplings, including smooth start-up, variable speed operation, shock absorption, efficiency, and durability. However, they can be more expensive and require more maintenance than other types of couplings.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Fluid Couplings in Marine Propulsion Systems

Yes, fluid couplings can be and are commonly used in marine propulsion systems. They offer several advantages that make them well-suited for such applications:

- Smooth Power Transmission: Fluid couplings provide smooth power transmission, which is beneficial for marine propulsion where abrupt changes in power delivery can be detrimental to the vessel’s stability and performance.

- Torque Limiting: In marine applications, fluid couplings can act as torque limiters, protecting the propulsion system and engine from sudden torque surges and overloads, which can occur during maneuvers or when encountering resistance in water.

- Impact Damping: The hydrodynamic principle of fluid couplings helps dampen impacts and shocks in the propulsion system, reducing wear and tear on the components and extending their lifespan.

- Load Sharing: In multi-engine marine setups, fluid couplings facilitate load sharing between engines, ensuring each engine contributes its share of power to achieve optimal propulsion efficiency.

- Start-up Performance: Fluid couplings enable controlled and gradual acceleration during start-up, which is crucial for large vessels and applications where sudden torque spikes could damage the drivetrain or disturb the vessel’s balance.

- Overload Protection: The fluid coupling’s ability to slip at high loads provides inherent overload protection to the marine propulsion system, safeguarding it against potential damage.

Fluid couplings used in marine applications are specially designed to withstand the harsh conditions of the marine environment, including exposure to saltwater, humidity, and vibration. They are available in various sizes and configurations to accommodate different marine vessel types and power requirements.

Overall, fluid couplings offer reliable and efficient power transmission solutions for marine propulsion systems, contributing to the safe and smooth operation of the vessel.

Fluid Coupling’s Handling of Load Changes during Operation

Fluid couplings are designed to efficiently handle changes in load conditions during operation, providing smooth and controlled power transmission. Here’s how fluid couplings accomplish this:

1. Torque Sensing: Fluid couplings are torque-sensitive devices. As the load on the driving side varies, the torque transmitted through the fluid coupling adjusts accordingly. When the load increases, the fluid coupling allows for some slip between the input and output sides, absorbing the excess torque. Conversely, when the load decreases, the fluid coupling reduces slip and transmits more torque, accommodating the new load conditions.

2. Load Distribution: In multi-drive systems, fluid couplings help to distribute the load evenly among connected equipment. When one machine experiences a higher load, the fluid coupling redistributes torque to prevent overloading of a specific component, ensuring a balanced power distribution.

3. Smooth Power Transmission: Fluid couplings offer a smooth and gradual transmission of power, even during load changes. Unlike mechanical clutches or direct couplings, fluid couplings provide a dampening effect, reducing shock loads and torsional vibrations when the load fluctuates. This minimizes stress on the connected machinery and enhances overall system reliability.

4. Soft Start and Stop: One of the significant advantages of fluid couplings is their ability to facilitate soft start and stop operations. During startup, the fluid coupling allows for controlled slip, gradually increasing the speed of the driven equipment. Similarly, during shutdown, the fluid coupling smoothly decelerates the connected machinery, preventing sudden stops that could cause damage or excessive wear.

5. Overload Protection: In situations where the load surpasses the rated capacity, the fluid coupling acts as an overload protector. By slipping and absorbing excess torque, it prevents damage to the connected equipment and the fluid coupling itself. This overload protection contributes to the safety and longevity of the entire system.

6. Automatic Adjustment: Fluid couplings automatically adjust to variations in load conditions without the need for manual intervention. This feature makes them suitable for applications with changing load demands, such as conveyors, crushers, pumps, and fans.

Overall, the ability of fluid couplings to handle changes in load conditions ensures stable and efficient power transmission while protecting the machinery from abrupt stress and wear. This makes fluid couplings an excellent choice for various industrial applications that require reliable and flexible power transfer.

Applications of Fluid Couplings in Industrial Machinery

Fluid couplings are widely used in various industrial machinery and equipment due to their unique characteristics and benefits. Some common applications include:

- Conveyors: Fluid couplings are used in conveyor systems to provide smooth start-ups and overload protection. They help in preventing damage to the conveyor belts and equipment during sudden starts and stops.

- Pumps: Fluid couplings are employed in pumps to control the acceleration and deceleration of the pump impeller. This ensures a gradual and controlled flow of fluids, reducing water hammer and pressure surges.

- Fans: Industrial fans often use fluid couplings to regulate fan speed and avoid abrupt changes in airflow, which can cause mechanical stress and system instability.

- Mining Equipment: Fluid couplings are used in mining machinery, such as crushers and conveyors, to protect the drivetrain from shock loads and to enhance equipment reliability.

- Marine Propulsion Systems: In marine applications, fluid couplings are used in propulsion systems to provide smooth engagement of the propeller, protecting the engine and transmission.

- Power Plants: Fluid couplings are utilized in power plants for boiler feed pumps, induced draft fans, and other equipment to achieve smooth operation and prevent sudden stress on mechanical components.

- Steel Industry: In steel mills, fluid couplings are employed in various equipment, including rolling mills and continuous casting machines, to protect the machinery and enhance productivity.

- Automotive: Fluid couplings are used in automatic transmissions to smoothly transmit power from the engine to the wheels, allowing smooth gear changes and preventing driveline shock.

- Wood Processing: In wood processing equipment, such as chippers and saws, fluid couplings are used to protect the equipment from shock loads and to achieve efficient power transmission.

Overall, fluid couplings play a crucial role in a wide range of industrial machinery applications, providing enhanced protection, smoother operation, and increased equipment longevity.

editor by CX 2024-04-22

by

Tags:

Leave a Reply